250 employees

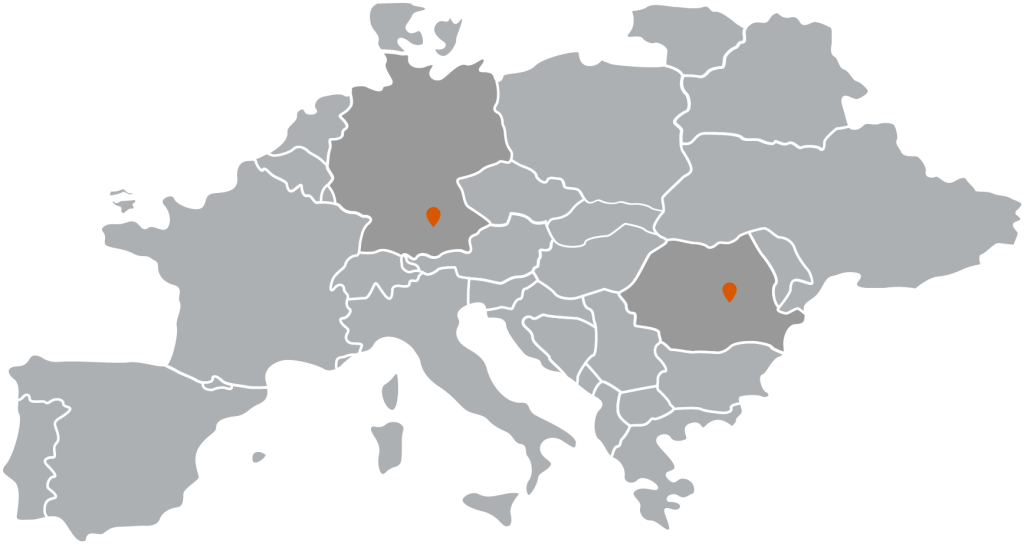

3 Sites

Production/stock 25.000 m²

ISO 9001:2015

The requirements of our customers are important to us.

We will be happy to support you in the realisation of your individual project ideas in the field of seat development from medium to large-scale production.

Our systems are tested according to the European Directives ECE R-14 and ECE R-16.

This means that our seating-, leg- and installation systems are compatible with each other and TÜV-tested.

Rental of our static tensile test facility is possible on request.

We are particularly proud of our roots in saddlery craftsmanship. To this day, we upholster our seats and sew the necessary covers ourselves.

This enables us to offer you a wide range of cover variations as well as individual embroidery and embossing.

In order to be able to offer our specialist partners the best product know-how, we carry out special product training for all Schnierle products.

The training courses can take place at our premises or at your site.

It all began in a rented truck garage in Augsburg. In the sixties – initially financially supported by his father - Hermann Schnierle benefited from the US-soldiers who were stationed in Augsburg and who invested a lot of money in their cars. The upholstery and saddlery workshops should rapidly flourish.

The still young craft business has grown significantly within a few years. The company’s specialisation in seating equipment for buses also made it necessary to move to larger premises in Königsbrunn. At the same time, Hermann Schnierle founded the Hermann Schnierle GmbH in 1977 and appointed Rainer Höfele as managing director, who was already closely involved in the development of the business at that point.

The upward trend continued unabated. As early as 1980, Schnierle expands production to include seat manufacturing for motorhomes. At the time, no one had any idea that 40 years later, due to a worldwide virus pandemic, the motorhome market would mean a completely new travel and leisure culture for people.

The path to industrial production was paved and found another high point in the expansion of the production of seats for minibuses and motorhomes with integrated 3-point belt.

This was associated with the need for larger administrative, production and storage space, which led to the move to the current headquarters in Gersthofen in 1991.

Shortly afterwards, Martin Schnierle was appointed managing director, who also helped steer the strategic direction of the company as another shareholder and laid the foundation for the future success story.

With increasing internationalisation of the markets, the focus was increasingly on the quality of the management and production processes, which resulted in the first ISO certification in 1995.

Martin Schnierle also invested in setting up its own tensile test facility, which is accredited be the renowned European testing institutes such as TÜV Rheinland (TÜV Automotive), RDW (NL), UTAC (UK), DTN (CH), and much more.

Schnierle has established itself over the decades as a competent partner for car body converters/builders and OEMs. Due to increasing customer demand for individual seat developments and designs, a massive expansion of the in-house design and development departmentwas undertaken.

The company’s core competencies are constantly being expanded. In addition to the department of upholstery and saddlery, the production of vehicle seats and seating systems, the range of installation and conversion systems, this was followed in 2010 by the patenting of a transport concept for vehicles suitable for the disabled, the Schnierle Rollibox®.

A strategically important decision was the foundation of Schnierle Safety Belts GmbH through the takeover of the former Schneeweis company. The production company of the safety belts and belt systems is located in Gersthofen.

Just in time for the company’s 50th anniversary, a new production hall was put into operation in Gersthofen. Since then, seat production for the motorhome sector has been taking place on an additional 2,200 m².

Production and storage capacities must be expanded. Schnierle founds the Schnierle S.r.l in Sfantu Gheorge, Romania. The company serves as an extended workbench for seating systems in Gersthofen and Schnierle Safety Belts in Laufen.

Schnierle takes additional 8,000 m² of production space for bench production, floor systems and Rollibox systems into operation in Augsburg.

Erweiterung Produktion und Lagerflächen in Augsburg/ Lechhausen um 7.100 m².

In December 2022, Rainer Höfele has left the company. After 45 years as Managing Director, he is taking a well-deserved retirement. His company shares were taken over by the Schnierle family. The Schnierle group of companies is thus a 100% family-run business.

Strategic involvement in the company

European Van Service GmbH.

Relocation of the Schnierle Safety Belts

company headquarters to Gersthofen.

Expansion of production space for vehicle construction by 2,000 m².

It all began in a rented truck garage in Augsburg. In the sixties – initially financially supported by his father - Hermann Schnierle benefited from the US-soldiers who were stationed in Augsburg and who invested a lot of money in their cars. The upholstery and saddlery workshops should rapidly flourish.

The still young craft business has grown significantly within a few years. The company’s specialisation in seating equipment for buses also made it necessary to move to larger premises in Königsbrunn. At the same time, Hermann Schnierle founded the Hermann Schnierle GmbH in 1977 and appointed Rainer Höfele as managing director, who was already closely involved in the development of the business at that point.

The upward trend continued unabated. As early as 1980, Schnierle expands production to include seat manufacturing for motorhomes. At the time, no one had any idea that 40 years later, due to a worldwide virus pandemic, the motorhome market would mean a completely new travel and leisure culture for people.

The path to industrial production was paved and found another high point in the expansion of the production of seats for minibuses and motorhomes with integrated 3-point belt.

This was associated with the need for larger administrative, production and storage space, which led to the move to the current headquarters in Gersthofen in 1991.

Shortly afterwards, Martin Schnierle was appointed managing director, who also helped steer the strategic direction of the company as another shareholder and laid the foundation for the future success story.

With increasing internationalisation of the markets, the focus was increasingly on the quality of the management and production processes, which resulted in the first ISO certification in 1995.

Martin Schnierle also invested in setting up its own tensile test facility, which is accredited be the renowned European testing institutes such as TÜV Rheinland (TÜV Automotive), RDW (NL), UTAC (UK), DTN (CH), and much more.

Schnierle has established itself over the decades as a competent partner for car body converters/builders and OEMs. Due to increasing customer demand for individual seat developments and designs, a massive expansion of the in-house design and development departmentwas undertaken.

The company’s core competencies are constantly being expanded. In addition to the department of upholstery and saddlery, the production of vehicle seats and seating systems, the range of installation and conversion systems, this was followed in 2010 by the patenting of a transport concept for vehicles suitable for the disabled, the Schnierle Rollibox®.

A strategically important decision was the foundation of Schnierle Safety Belts GmbH through the takeover of the former Schneeweis company. The production company of the safety belts and belt systems is located in Gersthofen.

Just in time for the company’s 50th anniversary, a new production hall was put into operation in Gersthofen. Since then, seat production for the motorhome sector has been taking place on an additional 2,200 m².

Production and storage capacities must be expanded. Schnierle founds the Schnierle S.r.l in Sfantu Gheorge, Romania. The company serves as an extended workbench for seating systems in Gersthofen and Schnierle Safety Belts in Laufen.

Schnierle takes additional 8,000 m² of production space for bench production, floor systems and Rollibox systems into operation in Augsburg.

Erweiterung Produktion und Lagerflächen in Augsburg/ Lechhausen um 7.100 m².

In December 2022, Rainer Höfele has left the company. After 45 years as Managing Director, he is taking a well-deserved retirement. His company shares were taken over by the Schnierle family. The Schnierle group of companies is thus a 100% family-run business.

Strategic involvement in the company

European Van Service GmbH.

Expansion of production space for vehicle construction by 2,000 m².

Relocation of the Schnierle Safety Belts

company headquarters to Gersthofen.

Patent applications for RelaX, RollerBase and FastEntry. RelaX, RollerBase and FastEntry.

Schnierle becomes a certified Ford Pro Converter.

It all began in a rented truck garage in Augsburg. In the sixties – initially financially supported by his father - Hermann Schnierle benefited from the US-soldiers who were stationed in Augsburg and who invested a lot of money in their cars. The upholstery and saddlery workshops should rapidly flourish.

The still young craft business has grown significantly within a few years. The company’s specialisation in seating equipment for buses also made it necessary to move to larger premises in Königsbrunn. At the same time, Hermann Schnierle founded the Hermann Schnierle GmbH in 1977 and appointed Rainer Höfele as managing director, who was already closely involved in the development of the business at that point.

The upward trend continued unabated. As early as 1980, Schnierle expands production to include seat manufacturing for motorhomes. At the time, no one had any idea that 40 years later, due to a worldwide virus pandemic, the motorhome market would mean a completely new travel and leisure culture for people.

The path to industrial production was paved and found another high point in the expansion of the production of seats for minibuses and motorhomes with integrated 3-point belt.

This was associated with the need for larger administrative, production and storage space, which led to the move to the current headquarters in Gersthofen in 1991.

Shortly afterwards, Martin Schnierle was appointed managing director, who also helped steer the strategic direction of the company as another shareholder and laid the foundation for the future success story.

With increasing internationalisation of the markets, the focus was increasingly on the quality of the management and production processes, which resulted in the first ISO certification in 1995.

Martin Schnierle also invested in setting up its own tensile test facility, which is accredited be the renowned European testing institutes such as TÜV Rheinland (TÜV Automotive), RDW (NL), UTAC (UK), DTN (CH), and much more.

Schnierle has established itself over the decades as a competent partner for car body converters/builders and OEMs. Due to increasing customer demand for individual seat developments and designs, a massive expansion of the in-house design and development departmentwas undertaken.

The company’s core competencies are constantly being expanded. In addition to the department of upholstery and saddlery, the production of vehicle seats and seating systems, the range of installation and conversion systems, this was followed in 2010 by the patenting of a transport concept for vehicles suitable for the disabled, the Schnierle Rollibox®.

A strategically important decision was the foundation of Schnierle Safety Belts GmbH through the takeover of the former Schneeweis company. The production company of the safety belts and belt systems is located in Gersthofen.

Just in time for the company’s 50th anniversary, a new production hall was put into operation in Gersthofen. Since then, seat production for the motorhome sector has been taking place on an additional 2,200 m².

Production and storage capacities must be expanded. Schnierle founds the Schnierle S.r.l in Sfantu Gheorge, Romania. The company serves as an extended workbench for seating systems in Gersthofen and Schnierle Safety Belts in Laufen.

Schnierle takes additional 8,000 m² of production space for bench production, floor systems and Rollibox systems into operation in Augsburg.

In December 2022, Rainer Höfele has left the company. After 45 years as Managing Director, he is taking a well-deserved retirement. His company shares were taken over by the Schnierle family. The Schnierle group of companies is thus a 100% family-run business.

Strategic involvement in the company

European Van Service GmbH.

Expansion of production space for vehicle construction by 2,000 m².

Relocation of the Schnierle Safety Belts

company headquarters to Gersthofen.

Patent applications for RelaX, RollerBase and FastEntry. RelaX, RollerBase, FastEntry and BoxPort.

Schnierle becomes a certified Ford Pro Converter.

Hermann Schnierle GmbH in Gersthofen and Augsburg-Lechhausen: Production of seats, vehicle floors, leg systems, and RolliBoxes®.

Schnierle Safety Belts in Gersthofen: Production of safety belts.

Schnierle S.r.l. in Romania: Extended workbench, sewing and assembly.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information